Uprooting and burying of weeds in between standing rows of rice crop in wetlands.

Two truncated rollers one behind other are fitted at the bottom of a long handle. The conical rollers have serrated blades on the periphery. A float provided in front portion prevents the unit from sinking into the soil. The cono weeder can also be used for trampling green manure crop in addition to weeding operation. It disturbs the top soil and increases aeration also. The equipment is operated in standing posture thus avoiding bending involved during uprooting of weeds by hands in traditional practice.

Capacity : 120 m2/h

Bending posture is avoided thus reducing drudgery of workers in weeding operation in wetlands.

Output is increased significantly.

Developed at: TNAU, Coimbatore

For line sowing of sprouted paddy seeds in puddle field.

It consists of drive wheels with lugs, drive shaft, hyperboloid shaped drums and swinging type pulling beam. The hyperboloid shaped drum enables free flow of seed towards the metering holes. In between two holes a baffle is provided for filling the drum with seeds. It has 18 holes of 10 mm diameter for dropping the sprouted seed in puddle field. The holes can be plugged depending on sprouted seeds and seed rate. A swinging handle is provided with the unit for pulling the seeder. Drum may be filled with pre-germinated/sprouted paddy seeds to its half of capacity. The method to prepare sprouted paddy seed is given in Annexure-II. After filling the drum, the lid of the drum may be closed and locked. The shallow ploughing/puddling of the field is required for proper operation of the equipment. After puddling excess water may be drained. From next morning operate the equipment at a walking speed of 1-1.5 km/h in the puddle field. The wheel impression during the previous pass will serve as a marker for the subsequent passes. During the operation of the equipment, dropping of seeds through the holes may be observed and drums may be refilled when the drum gets empty.

Capacity : 920 m2/h

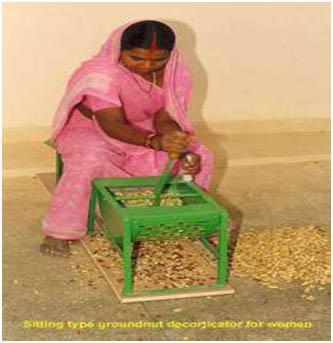

For separating kernels from groundnut pods.

A sitting groundnut decorticator is an oscillatory type device having cast iron shoes with projections for decortications of groundnut pods. It consist of frame, handle, oscillating arm and sieve with oblong hole. It is operated by a woman worker in sitting posture for which a stool is provided on a wooden platform. The pods are fed in batches of nearly 1.5 kg i.e. up to half of its hopper capacity so that oscillating arm can easily be operated. For proper decortications, the shoes, which are mounted on oscillating arm need to be adjusted. The women workers prefer the sitting type groundnut decorticator due to its low requirement of force and less cardiac cost.

Capacity : 30 kg/h

For stripping on groundnut pods.

The groundnut stripper consists of a square frame of vertical legs and a horizontal strip of expanded metal fixed on each side of the frame in the form of comb. The stripping of the pods is accomplished by drawing a handful of vines across the comb with a slight force. The structure facilitates its use by four women simultaneously. A small adjustable stool was fabricated for the operator to sit and perform the stripping operation. The height of the stool can be adjusted from 28-40 cm. this design eliminates knee pain and numbness while stripping in sitting posture at ground level. The frame was provided with telescopic support legs which enable the subjects to adjust the height of the frame from the ground level to suit their convenience to avoid postural discomfort. Also the hitting of the elbow against the abdomen while stripping is eliminated.

Capacity : 11 kg/h/women

Developed at: TNAU, Coimbatore

For cutting chaff/fodder/stalk into small pieces

This is a machine for cutting the chaff into the small pieces. The unit is provided with safety devices as per the Indian standard IS 7898. The machine is operated by rotating a flywheel on which the blades are mounted. Another person feeds the forage or grass through the feeding through. Dry or green fodder can easily be chopped with the machine.

For separating impurities like stubbles, chaff, dirt and broken received with grain after threshing.

It consists of main frame, grading screen, draper rod, rubber grip over handle, shutter etc. Four ropes are tied on the hooks provided on main frame of cleaner and hanged on any elevated point or hooks attached to the ceiling. It is operated in oscillating mode. The handle height of cleaner from ground should be at waist height of operator. Based on the size of grain, screen may be selected. Slow movement of cleaner is required after pouring grain on top of screen so that grain goes slowly down the cleaner box and chaff/ stubbles are remained on top of screen. After collecting the chaff from top of screen, gentle movement of cleaner is done to remove dirt, broken and finer chaff etc. present in the grain. Thereafter, it is taken out in a bag that is hanged on a sack holder by opening shutter of cleaner.

Capacity: 225 kg/h

Apart from 63% saving in cardiac cost of worker per unit of output, the productivity of the worker increased more than four times as compared to traditional thereby reducing drudgery.

Developed at: CIAE, Bhopal

For cleaning grain after harvesting.

This machine is easily operated and very useful for women farm workers. It consists of main frame, handle, gear mechanism, volute case, fan, hopper, outlets for clean grain and chaff. This machine can be operated by women worker by using hands in standing posture. Two women workers are required for operation of this machine, one woman operates the machine and other woman feeds the hopper and separates the cleaned grain. The machine can be easily operated by women while seating on chair or stool.

Capacity: 242 kg/h

Developed at: CRRI Cuttack

For threshing of paddy.

This thresher consists of a cylinder with wooden/aluminum strips. The wire loops are embedded/ welded on these strips. The cylinder is given a rotary motion from the foot pedal through a power transmission system. The paddy bundles are threshed with hold method.

Capacity: 35 kg/h

It helps to reduce the drudgery involved in paddy threshing operation as bending posture is avoided and arms are not to be raised for above shoulder height as in case of traditional method i.e. beating on a platform/stone.

Developed at: OUAT, Bhubaneswar

Department of Farm Machinery and Power, College of Agricultural Engineering and Technology, OUAT, Bhubaneswar- 751 003.

For stripping of sugarcane.

It is a hand tool for stripping of leaves and detopping of cane after harvest. The stripper works by separating and pushing the leaf sheaths away from stalk. A knife is welded on the stem of the stripper for detopping of canes and for cleaning roots etc.

Capacity: 46 kg/h

It helps to reduce the drudgery involved and chances of injury to workers in sugarcane stripping operation.

Developed at: IISR Lucknow and refined at OUAT Bhubaneswar

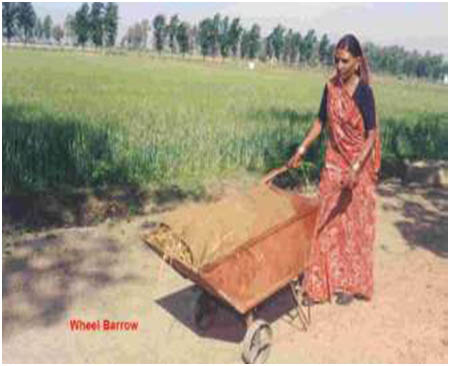

Carrying of agricultural materials

A wheel barrow is made of good quality mild steel sheet of 16 gauge (1.60 mm). It is found very useful to carry agricultural materials from one place to another. It is designed in such a way that the person does not have to exert much force in pulling/pushing the cart.

Capacity: 100 kg of load easily carried out by wheel barrow

A large amount of material can be carried from one place to another with less drudgery.

Developed at: Commercially available